Heavy duty

Headlight Loom

This is a good upgrade even for stock head lights

but even more so for those who run higher wattage globes ( bulbs in the US ).

Running higher watt globes on stock wiring will cause the wiring etc to over

heat and cause the lights to black out! Not what you want when rounding a bend

in the middle of the night at speed. Consider these facts on voltage drop. A

Halogen headlamp is rated to produce 100 % of its rated light output at 13.5V.

When voltage at the headlamp drops by 5 % to 12.82V the light output drops to 83

% of normal. When voltage drops by 10 % to 12.15V the light output drops to just

67 % of what it ought to be. A mere 1.35V of lost voltage has robbed you of 33 %

of your light output. And it gets worse as voltage is further reduced. These

figures come from a leading headlamp manufacturer and

this site. This setup will allow the use of 170/100W

globes to be used safely. You can use this setup for any brand of vehicle as you

don't even need to know anything about the wiring setup so long as they run H4

globes as all the switching is run from the plugs at the back of the headlight.

Even other globe types can still use this setup so long as you plug your switch

wires to trigger the relays into the high and low beam terminals.

|

Item |

Amount |

Description |

|

520 cm |

You need the red 6 mm wire for supplying

both the relays and the headlights high and low beam. 6 mm wire

falls closest to 10 AWG wire and is rated to carry 50 amps. |

|

260 cm |

This is black 6 mm wire to supply the

ground for the headlights. ( 10 AWG ) Use only automotive wire for

all connections or if in a salt area,

marine

boat wire is even better. |

|

160 cm |

This wire is only used to ground the

relay and as a switch wire from the old headlight plug. I used 2.5

mm wire which is around14 AWG. |

|

4 of |

To fit the 6 mm or 10 AWG wire to the

battery terminals for ground and to the front of the engine fuse box

for positive. Check your batter clamp bolts size. Mine were 1/4" |

|

6 of |

To connect the 6 mm or 10 AWG wire to

the relays |

|

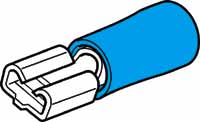

4 of |

To connect the 2.5 or 14 AWG wire to

the relay for the switch and ground wires. |

|

2 of |

To connect the 2.5 or 14 AWG wire to

the old headlight plug for the relay switch wires. Can also use a

male H4 plug to make it even neater.

http://www.rallylights.com/detail.aspx?ID=1421 |

|

2 of |

To connect the 2.5 or 14 AWG wire to

ground from the relays |

|

2 of |

Waterproof inline blade fuse holders and 30 amp fuses ( depends on

the wattage of bulbs used ). |

|

2 of |

New H4 headlight plugs. Buy the ones

without wires already on them from a auto electrician or if in the

USA,

http://www.comagination.com/ . Also here in the USA,

http://www.rallylights.com/detail.aspx?ID=1242 |

|

2 of |

Used one 40 amp for the high beam

and one 30 amp for the low beam. It makes it easier to identify them

but even a pair of 30 amp ones are enough for up to 130 watts with

still some head room. If you can, buy them with 5 pins ( 2x pin

87 for left and right headlight connections ) NAPA #AR274 Otherwise

just put both wires together into the one spade terminal. Or as I

have done since, two relays for each headlight, ( one for hi and one

for low per headlight ). That way more current and can only loose

one high or low per headlight at a time if a relay fails or fuse

blows. |

|

2 of |

You need 3 meters of 13 mm or 1/2"

split conduit and only 1/2 meter of 10 mm or 3/8" as well for the

switch wires. |

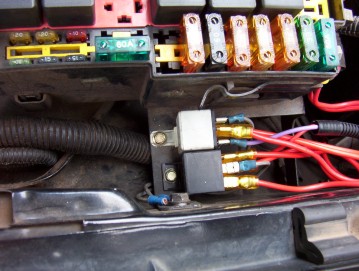

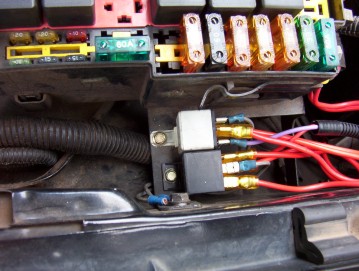

I started by wiring the relays. The black 30

amp relay on the left is for the low beams and the grey 40 amp one on the

right is for the high. You can just use two 30 amp ones but like using

a 40 amp one for the high beam to give plenty of head room for running 170w

globes. If you are running 2 relays for each headlight, you will need to

double up each one and run the switch wire to both pairs. Remember all wire lengths are based on the

fact that you fit them exactly where I have and on a Jeep XJ Cherokee. If you choose another location

for the relays all the measurements will have to change.

Wire A ( one for each relay ) above goes from pin 30 on the relay

using a yellow female spade at one end, to

power using a 1/4 ring terminal for the front of the fuse box at the other. This carries a 30

amp

blade fuse holder with water proof cap and came complete with the 6 mm wire needed

pre-assembled.

Wire

B ( one for each relay ) runs from pin 85 to ground on inner guard panel. It is

2.5 mm wire 20 cms long with a blue female spade at the relay end and a ring

terminal at the other to a ground screw.

Wire C runs from pin 86 to

the old headlight plug low beam socket ( top most terminal on the plug ) using a

blue male spade at one end and a blue female spade at the other for the relay.

It is 2.5 mm wire ( 14 AWG ) 60 cms long.

Wire D runs from pin 86 on the grey relay to the

high beam terminal on the old headlight plug using a blue male spade at one end

and a blue female spade at the relay end. It is 2.5

mm wire ( 14 AWG ) 60 cms long.

Assemble the headlight plugs as shown above

right. You will need three wires 60 cms long for the right headlight and three

200 cms long wires for the left side. Two red wires each side with yellow female

spade terminals at the relay end and the new headlight plugs female push in

terminals at the other. One black for each side with headlight plugs female push

in terminals at one end and yellow ring terminals to suit the negative battery

terminal bolt at the other.

I soldered and crimped them before pushing them into the holders headlight

holders.

Now time to join the relays to the headlight plugs. Wires not marked are

those already shown above in the first photos.

Wire E runs from the right headlight plug to pin

87 on the grey high beam relay and is 6 mm or 10 AWG wire 60 cms long.

Wire F runs from the right headlight plug to pin

87 on the black low beam relay and is 6 mm or 10 AWG wire 60 cms long.

Wire G goes from the right headlight plug to

ground on the battery and is 6 mm or 10 AWG wire 60 cms long.

Wire H runs from the left headlight plug to pin

87 on the grey high beam relay and is 6 mm or 10 AWG wire 200 cms long.

Wire I runs from the left headlight plug to pin

87 on the black low beam relay and is 6 mm or 10 AWG wire 200 cms long.

Wire J runs from the left headlight plug to

ground on the battery and is 6 mm or 10 AWG wire 200 cms long.

I encased the wire in split conduit to tidy in

all up as well as making it easier to run keeping it together and protected. The

three thick wires together in the 13 mm conduit for both left and right

headlights and the two switch wires together in a 10 mm one. I

mounted the relays on the support bracket for the fuse box. You can see also how

the relay grounds ( pin 85 ) use the fixing bolt of the same bracket as well.

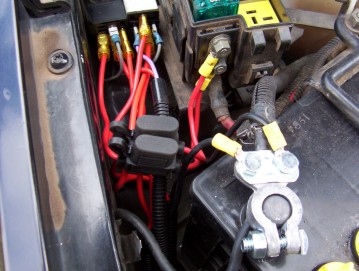

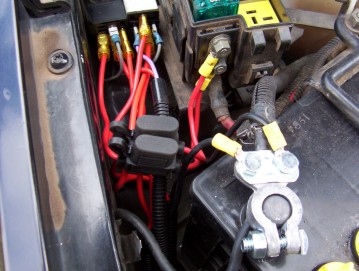

The two power supply wires from the relays ( pin

30 ) attached to the front of the fuse box where the power supply from the

battery is fixed. The cover slips back over nicely leaving them protected. The

two headlight ground wires from the plugs attached directly to the battery

terminal making sure the best possible supply. A body ground is not as good for

this many amps.

The photo above shows the switch wire connections

to the old headlight plug. The red wire ( wire C from the top photo ) goes in

the top most terminal and then to the black low beam relay on pin 86. The purple

wire ( wire D from the top photo ) goes in the left terminal and goes to pin 86

on the grey high beam relay. To run the loom across to the other headlight I

placed it behind the grill support frame as shown. It tucked in nicely between

that and the auto cooler brackets as shown with the left cooler bracket done and

right cooler bracket still not to show where it runs.

Even though the above photos have different exposures, they really were that

different with the left photo showing the new wiring and the right one still

plugged into the old wiring. They were much brighter and a whiter than before

now that there is no voltage drop. These were running 130/90W globes and if left

on high beam for too long they would cut out all together. Now no such problem

happens.

I have also been made aware that on some models with day time running lights (

DRL ) that it can cause problems. The easiest way to fix it is to disconnect the

DRL module. This will though stop the high bean light from coming on so to get

that to work, just jump the no.1 and no.4 terminals on the plug from the DRL

whose plug is pictured below to suit 90-98 years.

[Index]